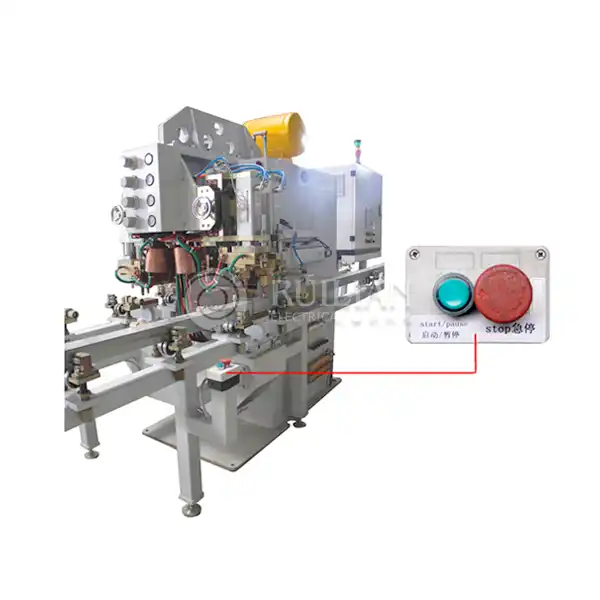

What is Security Door Assembly Spot Welding Machine?

We know how important it is to make high-quality doors that meet the highest security standards because we are a leading manufacturer of security door assembly spot welding machine. Your production line will run smoothly and effectively as a result of our machine's ability to manufacture secure doors in an effective and dependable manner.

Technical Parameters

| Parameter | Value |

|---|---|

| Power Supply | 380V/50Hz (Customizable) |

| Rated Capacity | 80 kVA(Customizable) |

| Welding Thickness | 0.5-5.0 mm |

| Electrode Stroke | 10 - 50mm |

| Welding Speed | Customizable |

| Control System | PLC |

| Cooling Method | Water Cooling |

| Dimensions (L×W×H) | According to the actual product |

| Weight | According to the actual product |

Product Features

| Feature | Description |

|---|---|

| High Precision | Computer-controlled for consistent spot welds, ensuring top-quality doors. |

| Customizable | Adjustable settings to accommodate various door sizes and designs. |

| Efficiency | Reduces manual labor, speeds up production, and lowers operational costs. |

| Durability | Built with high-grade materials to withstand continuous industrial use. |

| Safety Compliance | Meets international safety standards, reducing workplace hazards. |

| User-Friendly | Intuitive interface for easy operation, minimal training required. |

| After-Sales Support | Comprehensive technical support and maintenance services. |

Application Fields

1. Security Entryway Manufacturing: Ideal for gathering different sorts of safety entryways, including steel, aluminum, and composite materials.

2. Auto Industry: suitable for welding door panels, frames, and reinforcements, among other automotive parts.

3. Sector of construction: Utilized in the creation of metal designs, doors, walls, and other engineering components requiring exact welding.

4. Making appliances: Applied in the assembling of domestic devices, like fridges, broilers, and washing Security Door Assembly Spot Welding Machines, for consistent metal joining.

5. Modern Fabrication: Used to weld metal parts in structural assemblies, machinery, and equipment in a variety of industries.

Quality Control and Safety Standards

1. ISO Certification: Made in consistence with ISO 9001 quality administration guidelines, guaranteeing reliably top notch items.

2. CE Compliance: complies with CE safety standards, ensuring product dependability and safety.

3. Quality Assurance: Thorough testing and review processes approve execution and sturdiness, fulfilling industry guidelines and client assumptions.

4. Security Protocols: Integrates security highlights, for example, over-burden insurance, voltage observing, and crisis stop buttons to defend administrators and gear.

Why Choose RUILIAN?

Experience: Years of expertise in industrial manufacturing solutions.

Innovation: Continuously updated with the latest welding technology.

Reliability: Proven track record with global manufacturers.

Support: Dedicated customer service for setup, training, and maintenance.

Contact Us

We are a leading manufacturer of security door assembly spot welding machines, with years of experience in the industry. Our machines are designed to meet the highest security standards and are used by top manufacturers around the world. Contact RUILIAN at ry@china-ruilian.cn and hm@china-ruilian.cn.