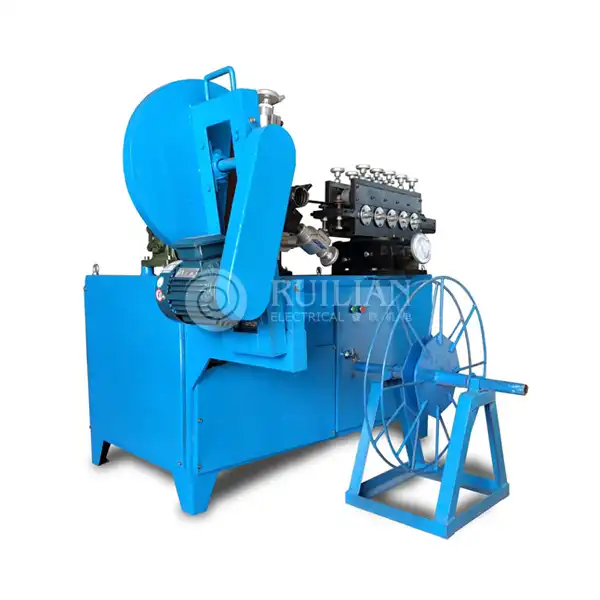

What is Automatic Seam Welding Machine?

Our Automatic Seam Welding Machine is designed for industries that demand high-quality, consistent, and efficient welding solutions. Whether you are in metal fabrication, automotive, aerospace, or energy sectors, our machine delivers the performance you need to stay ahead.

Technical Parameters

| Parameter | Specification |

|---|---|

| Welding Speed | 5 - 15m/min |

| Welding Thickness | 0.5 - 1.2 mm |

| Power Supply | 220V/380V , 50/60Hz |

| Welding Length | 100 - 1500mm |

| Motor Power | 150kW |

| Control System | PLC Control |

| Dimensions (L×W×H) | 3000×1500×1800 mm |

| Weight | 4000 kg |

Product Features

1.Automated Activity: The fully automated operation of the Automatic Seam Welding Machine reduces the need for manual intervention, improving efficiency and consistency.

2.High Accuracy: High level control frameworks guarantee exact arrangement and welding, bringing about perfect creases.

3.Variable Speed: Flexible welding speed takes into consideration customization in view of material sort and thickness.

4.User-Accommodating Point of interaction: Instinctive controls and point of interaction make activity simple and available for administrators of all expertise levels.

5.Compact Plan: Space-saving plan guarantees ideal use of floor space in modern settings.

Application Fields

1.Automotive Industry: Utilized for welding vehicle parts, for example, exhaust frameworks, gas tanks, and undercarriage.

2.Aerospace Area: Basic for manufacturing aviation structures, including fuselages, wings, and motor parts.

3.Construction Area: Ideal for joining underlying steel parts in building development and framework projects.

4.Manufacturing Industry: Utilized in the development of electric water heater manufacturing,apparatuses, hardware, and metal furnishings.

Quality Control and Safety Standards

1.ISO Certificate: Consistence with global quality administration guidelines guarantees steady quality and consumer loyalty.

2.Safety Highlights: Joining of security interlocks, crisis stop buttons, and defensive fenced in areas to forestall mishaps and guarantee administrator wellbeing.

3.Quality Confirmation: Thorough testing and review methods all through the assembling system to keep up with high item quality and dependability.

4.Documentation: Keep up with itemized records of creation cycles and quality control measures for recognizability and responsibility.

5.Continuous Improvement: Obligation to ceaseless improvement drives to upgrade item quality, effectiveness, and security guidelines.

Why Choose RUILIAN?

1.Innovative Arrangements: RUILIAN is famous for its imaginative welding arrangements custom-made to meet the assorted necessities of clients across different enterprises.

2.Quality Confirmation: With long periods of involvement and a guarantee to greatness, RUILIAN guarantees the best expectations of value and unwavering quality in its items.

3.Customer-Driven Approach: RUILIAN focuses on consumer loyalty, offering customized administrations and backing to address explicit prerequisites and difficulties.

4.Technical Ability: Upheld by a group of talented specialists and professionals, RUILIAN gives unrivaled specialized mastery and help to clients.

5.Proven History: With a strong history of conveying predominant welding arrangements, RUILIAN has procured the trust and unwaveringness of clients around the world.

FAQ

What materials can the machine weld?

The machine is versatile and can weld stainless steel, aluminum, and carbon steel.

How much training is required to operate the machine?

Our intuitive PLC control system requires minimal training. We provide comprehensive on-site training and support.

What is the lead time for delivery?

Typical lead times range from 4 to 8 weeks, depending on customization requirements.

Is technical support available after purchase?

Yes, we offer global technical support and maintenance services.

Contact Us

As a main Automatic Seam Welding Machine Manufacturer and Supplier, RUILIAN is focused on conveying creative arrangements, excellent quality, and prevalent client care. For requests and orders, kindly get in touch with us at ry@china-ruilian.cn and hm@china-ruilian.cn.