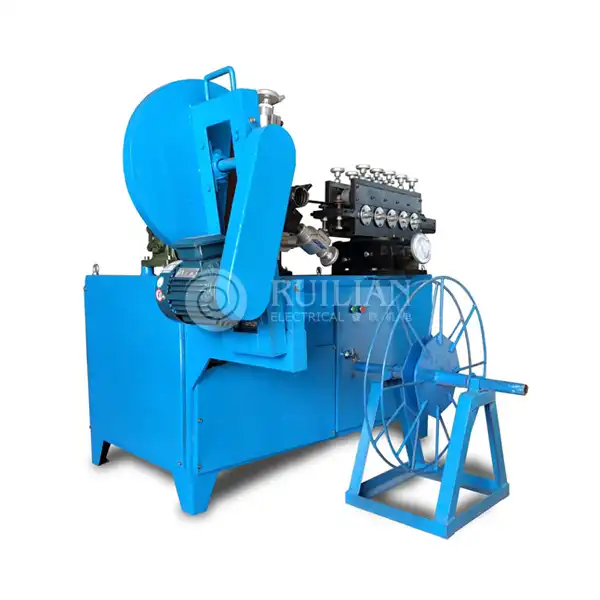

What is Seam Welding Customization Machine?

The Seam Welding Customization Machine is a state of the art piece of hardware intended to convey high accuracy, productivity, and dependability in different welding applications. This machine is explicitly engineered to meet the exceptional prerequisites of various ventures by offering customizable solutions that take care of explicit necessities. Whether you're associated with car fabricating, aviation, hardware, or some other area requiring exact seam welding, this machine guarantees first rate execution and sturdiness.

Technical Parameter

| Parameter | Specification |

|---|---|

| Welding Speed | 2 - 12m/min |

| Welding Thickness Range | 0.2- 3mm |

| Electrode Force | 500 - 10000 N |

| Power Supply | 220V/380V, 50/60 Hz |

| Control System | PLC (Programmable Logic Controller) |

| Cooling System | Water-cooled |

| Machine Dimensions | Customizable |

| Weight | 700 - 3000 kg (depending on configuration) |

| Welding Method | Continuous/Intermittent |

| Electrode Material | Copper Alloy |

Product Features

The Seam Welding Customization Machine boasts several innovative features designed to enhance its performance and usability:

- Customizable Configuration:Tailored to meet specific industrial requirements, allowing for modifications in dimensions, welding speed, and power supply.

- Advanced Control System:Equipped with a PLC for precise control of welding parameters, ensuring consistent quality and efficiency.

- High Welding Speed:Capable of welding at speeds ranging from 1 to 20 meters per minute, significantly improving production efficiency.

- Versatile Welding Range:Suitable for welding thicknesses from 0.1 mm to 10 mm, accommodating a wide range of materials and applications.

- Durable Electrode Materials:Utilizes high-quality copper alloy electrodes, ensuring excellent conductivity and durability.

- Efficient Cooling System:Features a robust water cooling system that maintains optimal operating temperatures and extends the lifespan of machine components.

- User-Friendly Interface:Intuitive control panel and interface, making it easy for operators to set parameters and monitor the welding process.

Application Fields

The welding line is highly versatile and finds applications across various industries:

- Automotive Industry:Used for welding components such as fuel tanks, exhaust systems, and structural parts, ensuring strong and reliable joints.

- Aerospace Industry:Ideal for welding lightweight and high-strength materials used in aircraft structures and components.

- Electronics Industry:Employed in the production of electronic enclosures and battery packs, where precision and reliability are critical.

- Medical Devices:Used for welding components of medical devices and equipment, ensuring sterile and robust joints.

- Consumer Goods:Applicable in the manufacturing of appliances and metal furniture, providing aesthetically pleasing and durable welds.

Certification:

Sticking to rigid quality control and security guidelines is crucial for the dependable activity of the Machine:

Why Choose Us?

Choosing our Machine comes with several advantages:

- Industry Expertise:With years of experience in manufacturing seam welding machines, we understand the unique needs of various industries.

- Innovation:Continuous research and development efforts ensure our machines incorporate the latest technologies and advancements.

- Customization:We offer fully customizable solutions to meet the specific requirements of our customers.

Contact Us

RUILIAN, an expert manufacturer and supplier with numerous long stretches of creation experience in Seam Welding Customization Machines, contact us at ry@china-ruilian.cn and hm@china-ruilian.cn.