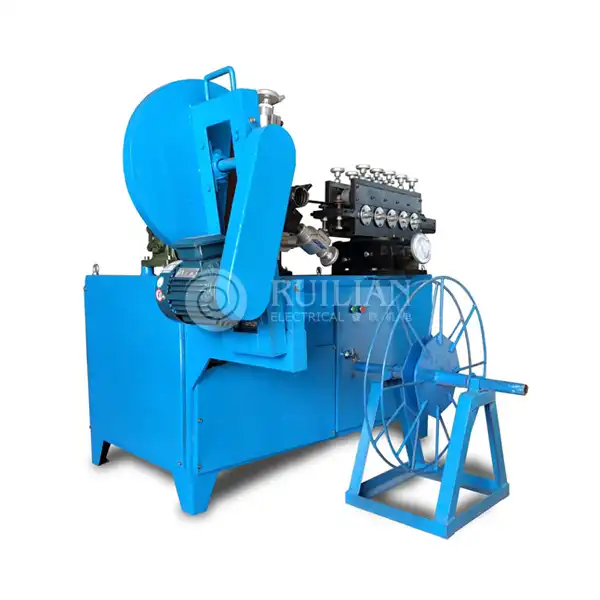

What is Roll Forming Machine?

The Roll Forming Machine is a crucial development in the metalworking business, empowering the effective and exact creation of nonstop, uniform shapes from metal curls. This best in class hardware is instrumental in the assembling of a wide cluster of metal items, including material boards, auto parts, and underlying parts.

Our Roll Forming Machines are designed to meet the highest standards of quality and performance, catering to a wide range of industries including construction, automotive, home appliances, aerospace, and furniture manufacturing. Explore our specifications, features, applications, certifications, and discover why choosing us will benefit your business.

Technical Parameters:

Understanding the technical specifications of the Roll Forming Machine is crucial for evaluating its performance and suitability for specific manufacturing requirements. Below is a detailed table outlining the key technical parameters:

| Parameter | Specification |

|---|---|

| Forming Material | Steel, Aluminum, etc. |

| Material Thickness | 0.3 - 1.5 mm |

| Coil Width | 50 - 1500 mm |

| Forming Speed | Up to 15 pieces/minute |

| Number of Rollers | 3 - 5 pairs |

| Control System | PLC Control |

| Drive System | Electric / Hydraulic |

| Machine Dimensions (L x W x H) | Variable based on model |

| Weight | 5000 - 20000 kg |

| Certification | ISO 9001:2015, CE |

Product Features:

High Precision: Advanced CNC technology ensures precise forming.

Durability: High-quality materials and components for long-lasting performance.

Efficiency: High-speed production with minimal downtime.

Customization: Tailored solutions to meet specific client requirements.

User-Friendly Interface: Easy-to-use PLC control with touch screen.

Technical Advantages:

1. Efficiency: The continuous forming process and high-speed operation significantly boost production efficiency compared to traditional methods.

2. Consistency: The machine produces consistent and uniform profiles, reducing the need for secondary processing and minimizing waste.3. Cost-Effectiveness: Via robotizing the framing system, work costs are diminished, and creation times are abbreviated, prompting lower in general assembling costs.

4. Flexibility: The machine can be rapidly reconfigured to create various profiles, permitting producers to answer quickly to changing business sector requests.

5. Control of Quality: Coordinated quality control frameworks guarantee that every item satisfies tough guidelines, upgrading by and large item quality.

Application Fields:

Construction: C-Purlin, Z-Purlin, Roofing Panels, Wall Panels, Metal Stud Framing

Automotive: Body Panels, Structural Components, Trim Pieces

Appliances: Refrigerator Panels, Washing Machine Cabinets, HVAC Ductwork

Furniture: Metal Furniture Frames, Shelving Systems

Storage & Logistics: Racking Systems, Pallet Racking

Why Choose RUILIAN?

RUILIAN is a renowned leader in industrial equipment manufacturing, known for delivering state-of-the-art solutions tailored to the evolving needs of the manufacturing industry. Here’s why you should choose RUILIAN:

Experience and Expertise: Over 20 years in the roll forming industry.

Quality Assurance: Rigorous quality control processes to ensure high standards.

Customer Support: Comprehensive after-sales service and technical support.

Innovation: Continuous investment in the latest technology and R&D.

Global Reach: Serving clients worldwide with reliable delivery and support.

FAQ:

Q: What is the lead time for a custom roll forming machine?

A: Lead times vary depending on the complexity of the machine. Contact us for a specific quote.

Q: What types of materials can your machines process?

A: Our machines can handle a variety of materials, including steel, aluminum, and stainless steel.

Q: Do you offer training on machine operation and maintenance?

A: Yes, we provide comprehensive training programs to ensure optimal machine performance.

Contact Us

As a trusted Roll Forming Machine manufacturer and supplier with extensive experience, RUILIAN is your ideal partner in elevating your manufacturing capabilities. For inquiries and customized solutions, contact ry@china-ruilian.cn and hm@china-ruilian.cn.