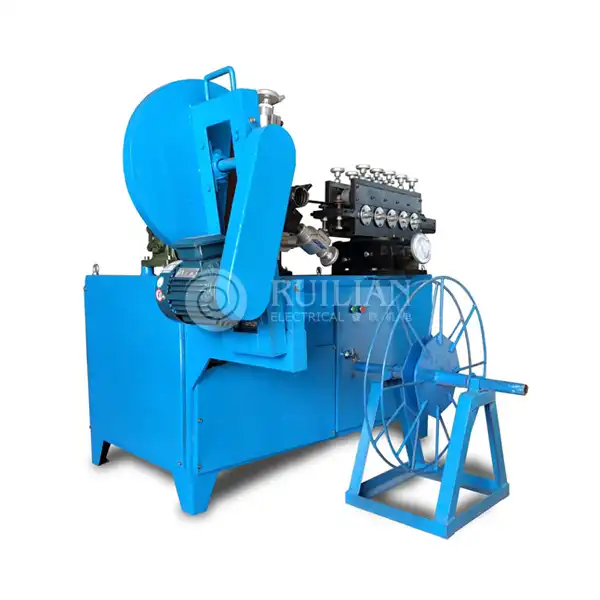

What is Air Duct Combination Machine?

In the realm of HVAC (Heating, Ventilation, and Air Conditioning) systems, efficiency and precision are paramount. The Air Duct Combination Machine emerges as a technological marvel, revolutionizing the fabrication process of air ducts with its advanced capabilities. From enhancing airflow to ensuring structural integrity, this machine sets new standards of excellence in ductwork manufacturing, catering to the diverse needs of industries worldwide.

Technical Parameters

| Parameter | Specification |

|---|---|

| Maximum Duct Diameter | Up to 1250mm |

| Cutting Thickness | 0.5mm - 1.5mm |

| Forming Speed | Adjustable, up to 9m/min |

| Motor Power | 7.5kW |

| Control System | PLC Control |

Product Features

High Efficiency: Streamline your production process with automated operations that reduce manual labor and boost productivity.

Cost-Effective: Minimize operational costs with a single machine that performs multiple tasks, reducing the need for multiple pieces of equipment.

Precision Manufacturing: Achieve consistent, high-quality output with advanced technology that ensures accurate cuts and bends.

Durable Construction: Built with industrial-grade materials to withstand continuous, heavy-duty operation.

User-Friendly Interface: Simplified controls and easy-to-navigate software make it accessible for operators of all skill levels.

Application Fields

HVAC Manufacturing: Ideal for large-scale production of air ducts for heating, ventilation, and air conditioning systems.

Construction: Perfect for contractors and construction companies involved in large building projects.

Metal Fabrication: Suitable for metalworking shops looking to expand their capabilities.

Public Infrastructure: Used in the production of ducts for public buildings, hospitals, and government facilities.

Compatible Projects:

Commercial Buildings: Shopping malls, office complexes, hotels.

Industrial Facilities: Factories, warehouses, and production plants.

Residential Projects: Large or small-scale housing developments.

Public Projects: Airports, train stations, and municipal buildings.

Quality Control and Safety Standards

All our machines undergo rigorous testing and quality checks before shipment. We adhere to international safety standards and are ISO 9001 certified, ensuring you receive only the best.

Why Choose Us?

1.Industry Leadership: With extensive experience in manufacturing precision machinery, we are a trusted leader in the field of ductwork fabrication equipment.

2.Innovation and Technology: Our commitment to innovation drives the development of cutting-edge solutions that empower businesses to excel in their respective industries.

3.Quality Assurance: Rigorous quality control measures and attention to detail ensure that our machines deliver unparalleled performance and reliability.

4.Customer-Centric Approach: We prioritize customer satisfaction, offering personalized solutions, responsive support, and seamless service experiences.

FAQ:

Q: What materials can the Air Duct Combination Machine process?

A: The machine is compatible with galvanized steel, stainless steel, aluminum, and copper.

Q: Is the machine suitable for small-scale operations?

A: Yes, while it's designed for high efficiency, it's also scalable for smaller production needs.

Q: Do you offer training for machine operators?

A: Yes, we provide comprehensive training and support to ensure your team is fully equipped to operate the machine.

Q: What are the warranty terms?

A: The machine comes with a standard 24-month warranty, with options for extended coverage.

Contact Us

As a professional Air Duct Combination Machine manufacturer and supplier with years of experience, RUILIAN is your trusted partner in achieving manufacturing excellence. For inquiries and orders, please contact us at ry@china-ruilian.cn and hm@china-ruilian.cn.