Advanced Servo Motor Technology: Precision and Control

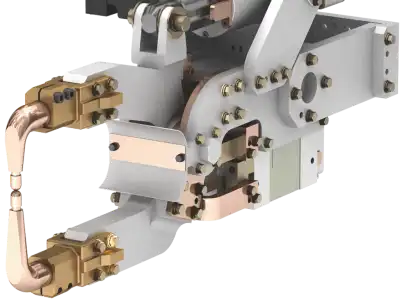

One of the most significant technological advancements in servo portable spot welding machines is the incorporation of servo motor technology. Unlike traditional spot welding machines that rely on pneumatic or hydraulic systems, servo-driven models utilize electric servo motors to control the welding process with unprecedented accuracy and consistency.

Servo motors offer several advantages over conventional actuation systems:

- Precise Force Control: Servo motors allow for extremely precise control over the welding force applied during the spot welding process. This level of control ensures consistent weld quality across multiple welds, even when working with materials of varying thicknesses or compositions.

- Dynamic Force Adjustment: The servo system can rapidly adjust the welding force in real-time, adapting to changes in material properties or environmental conditions. This dynamic adjustment capability results in more reliable welds and reduces the likelihood of defects.

- Programmable Weld Profiles: Servo-driven machines offer the ability to program and store multiple weld profiles, allowing operators to quickly switch between different welding parameters for various materials or applications. This feature enhances versatility and reduces setup time between welding tasks.

- Energy Efficiency: Servo motors are inherently more energy-efficient than pneumatic or hydraulic systems, as they only consume power when actively moving. This translates to lower operating costs and reduced environmental impact.

The integration of servo motor technology in portable spot welding machines has significantly elevated the precision and control available to welders. This advancement allows for the creation of high-quality welds with remarkable consistency, even in challenging applications or when working with sensitive materials.

Enhanced Portability and Ergonomics: Redefining Mobility

While traditional spot welding machines often require fixed installations or cumbersome setups, servo portable spot welding machines have been designed with mobility and user comfort in mind. These technological improvements have made spot welding more accessible and efficient in a wider range of environments and applications.

Key advancements in portability and ergonomics include:

- Lightweight Design: Servo portable spot welding machines often incorporate lightweight materials and compact components, significantly reducing the overall weight of the device. This makes it easier for operators to maneuver the machine and work in tight spaces or awkward positions.

- Balanced Construction: The internal components of servo portable spot welding machines are carefully arranged to optimize balance and weight distribution. This ergonomic design reduces operator fatigue during extended use and improves overall control and precision.

- Modular Components: Many servo portable spot welding machines feature modular designs that allow for easy customization and maintenance. This modularity enables users to adapt the machine to specific applications or quickly replace components without the need for specialized tools or extensive downtime.

- Integrated Cooling Systems: Advanced cooling technologies integrated into servo portable spot welding machines help maintain optimal operating temperatures, even during prolonged use. This feature extends the machine's duty cycle and ensures consistent performance in demanding environments.

The enhanced portability and ergonomic design of servo portable spot welding machines have expanded their applicability across various industries. These improvements allow for greater flexibility in production layouts, easier integration into existing workflows, and improved operator comfort and productivity.

Intelligent Control Systems: Data-Driven Welding

Perhaps one of the most transformative technological advancements in servo portable spot welding machines is the integration of intelligent control systems. These sophisticated electronic brains elevate spot welding from a purely mechanical process to a data-driven, adaptive operation.

Key features of intelligent control systems in servo portable spot welding machines include:

- Real-Time Monitoring: Advanced sensors continuously monitor critical welding parameters such as current, voltage, and electrode force. This real-time data allows the machine to make instantaneous adjustments to maintain optimal welding conditions.

- Adaptive Control Algorithms: Sophisticated software algorithms analyze the welding process in real-time and automatically adjust parameters to compensate for variations in material properties, surface conditions, or environmental factors. This adaptive capability ensures consistent weld quality across a wide range of applications.

- Data Logging and Analysis: Intelligent control systems can record detailed welding data for each spot weld, including time, date, welding parameters, and quality metrics. This information can be used for quality control, process optimization, and troubleshooting purposes.

- Network Connectivity: Many servo portable spot welding machines now offer network connectivity options, allowing for remote monitoring, data collection, and integration with broader manufacturing execution systems (MES) or enterprise resource planning (ERP) platforms.

- User-Friendly Interfaces: Modern servo portable spot welding machines often feature intuitive touchscreen interfaces or mobile app controls, making it easier for operators to adjust settings, monitor performance, and access welding data.

The integration of intelligent control systems in servo portable spot welding machines has revolutionized the welding process, offering unprecedented levels of control, consistency, and traceability. These advancements not only improve weld quality but also contribute to increased productivity, reduced waste, and enhanced overall equipment effectiveness (OEE).

In conclusion, the technology embedded in servo portable spot welding machines represents a significant leap forward from traditional models. The combination of advanced servo motor technology, enhanced portability and ergonomics, and intelligent control systems has transformed spot welding into a more precise, efficient, and versatile process. These technological advancements have expanded the applicability of spot welding across various industries and applications, offering improved weld quality, increased productivity, and better overall performance.

As welding technology continues to evolve, servo portable spot welding machines stand at the forefront of innovation, providing users with powerful tools to meet the demanding requirements of modern manufacturing and fabrication processes. By embracing these advanced technologies, businesses can stay competitive in an increasingly challenging global market, producing higher quality products with greater efficiency and reliability.

For more information about our range of servo portable spot welding machines and other welding solutions, please visit our website at www.rlseamwelding.com or contact us directly at ry@china-ruilian.cn. Our team of experts is ready to help you find the perfect welding solution for your specific needs and applications.