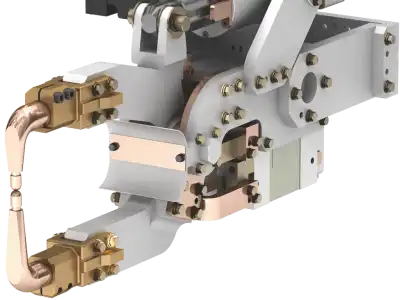

Spot welding machines, particularly those utilizing medium frequency technology, have found their way into numerous manufacturing sectors. From automotive assembly lines to aerospace component production, these machines play a crucial role in creating strong, durable joints between metal parts. As we explore the applications of spot welding machines, we'll uncover the unique advantages that medium frequency technology brings to the table, making it a preferred choice for many manufacturers.

Automotive Industry: Precision and Efficiency in Vehicle Assembly

The automotive industry stands as one of the most significant beneficiaries of spot welding technology, particularly medium frequency spot welding machines. These machines have become integral to vehicle assembly processes, offering unparalleled precision and efficiency in joining various components of a car's body and frame.

Medium Frequency Spot Welding Machines excel in automotive applications due to their ability to produce high-quality welds consistently. They are particularly adept at handling the thin, high-strength steel sheets commonly used in modern vehicle construction. The controlled heat input of medium frequency technology ensures that these delicate materials are welded without warping or compromising their structural integrity.

In automotive assembly lines, these machines are used to join body panels, create door frames, and assemble structural components. The speed and accuracy of medium frequency spot welding contribute significantly to the overall efficiency of the production process. Moreover, the ability to adjust welding parameters quickly allows for seamless transitions between different materials and thicknesses, a crucial feature in the diverse landscape of automotive manufacturing.

The durability of spot welds produced by medium frequency machines is another critical factor in their widespread adoption in the automotive sector. These welds must withstand the rigors of daily use, including vibrations, temperature fluctuations, and potential impacts. The consistent, high-quality joints created by medium frequency spot welding machines ensure that vehicles maintain their structural integrity throughout their lifespan, contributing to improved safety and longevity.

Home Appliance Manufacturing: Enhancing Durability and Aesthetics

The home appliance industry has embraced spot welding technology, with Medium Frequency Spot Welding Machines playing a pivotal role in the production of durable and aesthetically pleasing products. From refrigerators to washing machines, these welding machines contribute to the robust construction and sleek appearance of many household items we use daily.

In appliance manufacturing, medium frequency spot welding machines are prized for their ability to create strong, invisible joints. This capability is particularly valuable when working with stainless steel, a common material in high-end appliances. The controlled heat input of medium frequency technology allows for precise welding that doesn't mar the surface of the metal, maintaining the appliance's polished appearance.

The versatility of medium frequency spot welding machines is evident in their application across various appliance components. They are used to assemble refrigerator cabinets, secure washing machine drums, and join the internal components of dishwashers. The consistency and reliability of these machines ensure that each weld meets the stringent quality standards required in the competitive appliance market.

Energy efficiency is another area where medium frequency spot welding machines excel in appliance manufacturing. The precise control over the welding process allows for optimized energy consumption, reducing production costs and aligning with the industry's growing focus on sustainable manufacturing practices. This efficiency extends to the production line as well, with the high-speed capabilities of these machines contributing to increased output and reduced lead times.

Aerospace and Aviation: Meeting Stringent Quality Standards

The aerospace industry demands the highest levels of precision and quality in manufacturing processes, making it an ideal application for Medium Frequency Spot Welding Machines. These machines have found their place in the production of aircraft components, spacecraft parts, and satellite structures, where the integrity of every weld is crucial to safety and performance.

Medium frequency spot welding technology offers several advantages that are particularly relevant to aerospace applications. The ability to control the heat input with exceptional accuracy allows for welding of specialized alloys commonly used in aircraft construction, such as titanium and aluminum alloys. These materials often require precise temperature control to maintain their properties and prevent distortion or weakening of the surrounding material.

In the production of aircraft fuselages and wing structures, medium frequency spot welding machines are used to create strong, lightweight joints. The consistency of the welds produced by these machines is crucial in ensuring the structural integrity of the aircraft, which must withstand extreme conditions during flight. The non-destructive nature of spot welding also preserves the aerodynamic properties of the welded components, a critical factor in aircraft design.

The aerospace industry's stringent quality control requirements are well-matched by the capabilities of medium frequency spot welding machines. These machines often come equipped with advanced monitoring systems that can track and record welding parameters for each spot weld. This level of documentation is invaluable for quality assurance and traceability, allowing manufacturers to demonstrate compliance with industry standards and regulations.

As the aerospace industry continues to push the boundaries of technology, medium frequency spot welding machines are evolving to meet new challenges. Innovations in weld monitoring, adaptive control systems, and integration with robotic systems are enhancing the capabilities of these machines, ensuring they remain at the forefront of aerospace manufacturing technology.

Conclusion

In conclusion, the applications of spot welding machines, particularly Medium Frequency Spot Welding Machines, span a wide range of manufacturing sectors. From automotive assembly to home appliance production and aerospace engineering, these machines have proven their worth in creating strong, reliable joints while meeting the unique demands of each industry. As manufacturing technology continues to advance, we can expect to see even more innovative applications for these versatile welding solutions.

At RUILIAN, we're committed to providing cutting-edge welding solutions that meet the diverse needs of modern manufacturing. Our range of spot welding machines, including advanced Medium Frequency Spot Welding Machines, are designed to deliver the precision, efficiency, and reliability that today's industries demand. Whether you're in the automotive, appliance, aerospace, or any other manufacturing sector, we have the expertise and technology to support your welding needs. To explore how our solutions can enhance your manufacturing processes, please reach out to us at ry@china-ruilian.cn or visit our website at www.rlseamwelding.com.