The Mechanics Behind Seam Welding Ring Welding Machines

To truly appreciate the capabilities of a seam welding ring welding machine, it's essential to understand its underlying mechanics. These machines operate on the principle of resistance welding, where electrical current is passed through the metal pieces to be joined. The resistance of the metal to this current generates heat, which melts the metal at the point of contact, creating a strong, seamless weld.

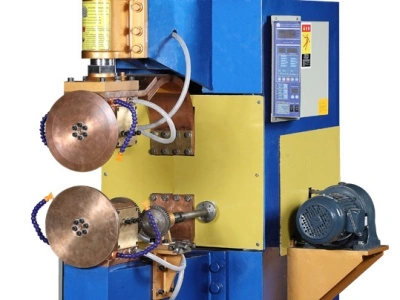

In a seam welding ring welding machine, this process is applied continuously along the circumference of the workpiece. The machine typically consists of two copper alloy wheel electrodes that rotate as they apply pressure to the overlapping edges of the metal being welded. As the workpiece rotates between these electrodes, a continuous weld is formed.

One of the key advantages of this method is the absence of filler material. The weld is created purely from the base metal, resulting in a joint that's as strong as the original material. This feature is particularly beneficial in applications where the integrity of the weld is crucial, such as in pressure vessels or food-grade containers.

Modern seam welding ring welding machines are often equipped with advanced control systems that allow for precise adjustment of welding parameters. These may include current intensity, electrode pressure, and rotation speed. Such fine-tuning capabilities ensure optimal weld quality across a wide range of materials and thicknesses.

Primary Applications of Seam Welding Ring Welding Machines

The versatility of seam welding ring welding machines has led to their adoption across numerous industries. Let's explore some of the primary applications where these machines excel:

Home Appliance Manufacturing: In the production of washing machines, dryers, and water heaters, seam welding ring welding machines are indispensable. They're used to create watertight drums and tanks, ensuring the longevity and reliability of these household essentials.

Automotive Industry: Fuel tanks, mufflers, and catalytic converters often require circular welds that are both strong and leak-proof. Seam welding ring welding machines provide the perfect solution for these components, contributing to vehicle safety and performance.

Aerospace: In the aerospace industry, where precision and reliability are non-negotiable, these machines are used to manufacture fuel tanks, pressure vessels, and other critical components. The consistency and strength of the welds produced are vital in ensuring the safety and efficiency of aircraft.

Food and Beverage Industry: Stainless steel tanks and vessels used in food and beverage processing require sanitary, smooth welds to prevent bacterial growth. Seam welding ring welding machines deliver these clean, crevice-free joints, making them ideal for this hygiene-critical industry.

HVAC and Ventilation: In the production of ducting and air handling units, these machines are used to create airtight seams. This is crucial for maintaining energy efficiency and ensuring proper air distribution in heating, ventilation, and air conditioning systems.

Oil and Gas: The petrochemical industry relies on seam welding ring welding machines for the production of pipelines, storage tanks, and pressure vessels. The ability to create long, continuous welds is particularly valuable in this sector.

Advantages and Considerations of Seam Welding Ring Welding Machines

While seam welding ring welding machines offer numerous benefits, it's important to consider both their advantages and limitations when evaluating their suitability for a particular application.

Advantages:

High Production Speed: These machines can produce welds much faster than manual welding methods, significantly boosting productivity in high-volume manufacturing environments.

Consistent Weld Quality: The automated nature of the process ensures uniformity in weld quality, reducing the risk of defects and the need for rework.

Energy Efficiency: Compared to other welding methods, seam welding is relatively energy-efficient, as heat is generated only at the point of welding.

Clean Welds: The process produces clean, spatter-free welds, which is particularly beneficial in applications where aesthetics or hygiene are important.

Versatility: These machines can handle a wide range of materials and thicknesses, making them suitable for diverse applications.

Considerations:

Initial Investment: The specialized nature of these machines means they can represent a significant upfront cost. However, their efficiency and longevity often result in a favorable return on investment over time.

Material Limitations: While versatile, these machines are primarily designed for welding metal. They may not be suitable for non-metallic materials or certain exotic alloys.

Size Constraints: The size of the workpiece that can be welded is limited by the machine's design. Very large or small diameter pieces may require specialized equipment.

Skill Requirements: While the welding process itself is automated, operators need specialized training to set up the machine correctly and troubleshoot any issues that arise.

In conclusion, seam welding ring welding machines represent a pinnacle of welding technology, offering unparalleled efficiency and quality in the production of circular welds. Their ability to create strong, leak-proof joints has made them indispensable in a wide range of industries, from home appliance manufacturing to aerospace engineering. As with any specialized equipment, the key to maximizing their potential lies in understanding their capabilities and limitations, and applying them to the right tasks.

At RUILIAN, we're committed to helping our clients harness the full potential of seam welding ring welding machines. Our team of experts is always ready to provide guidance on selecting the right equipment for your specific needs. Whether you're in the market for a new machine or seeking to optimize your existing welding processes, we're here to help. Reach out to us at ry@china-ruilian.cn or visit www.rlseamwelding.com to explore how our seam welding solutions can elevate your manufacturing capabilities.